SALZBURG MT 18 Grain Mill

$4,798.00

The semi commercial grain flour mill for the professionals

Are you a speciality baker ? looking for a “very special professional hand made grain mill”

- Do you also want to grind all hard grains in larger quantities?

- Do you value natural materials?

- Are you looking for a grain mill with a powerful industrial motor that grinds gently at low speeds producing QUALTY FINE FLOUR ?

- Do you want a grain mill that still has an attractive appearance despite its size?

- Are you an absolute grain mill lover ? looking for a “very special grain mill”

The inner milling chamber is made of wood, each granite mill-stone is hand made, true craftsmanship, a mill for professionals, a mill for life

- Grinds 270-580 grams per minute

- 120 mm Stone Diameter

- 900 Watt Electric Motor

- 1,700 gram Hopper

- Height 47cm / Weight 24 kg

- 12 year Product Warranty / 24 year Granite Stone Warranty

Delivery 4-6 week factory back-order

Description

Salzburg Mill Design – Quality & Style

Your grain mill should give you pleasure and always have a permanent place in your Bakery.

Your grain mill should give you pleasure and always have a permanent place in your Bakery.

900 Watt Electric Motor / 120 mm Natural Granite Stone

Salzburg Granite Stone

The heart of the grain mill is the millstone.

Based on experience and full conviction, it was decided in 2016 to manufacture mills exclusively with granite grinding stones quarried in nature

The decisive factors for this decision were the convincing features

The decisive factors for this decision were the convincing features

- Extreme longevity

- Almost unbreakable

- The exclusively natural abrasion – without artificial additives

- Self-sharpening

- The fineness and baking properties of the flour

The size of the grinding stone is not decisive for the fineness of the flour.

However, the optimum coordination of grinding stone diameter and motor speed is of great importance. This, combined with the heat and optimised grinder geometry, ensures gentle grinding of the grain.

The GRANITE mined in nature is carefully selected and completely natural – free from additives – pure nature!

- Granite is characterised by high wear resistance and is harder than some types of steel.

- Granite is naturally perfectly bonded (without any binding agent), self-sharpening and proven to be durable.

- To date, we are not aware of any allergic reactions to the granite grinding stone.

- We are not aware of any breakage or chipping of stone particles (due to grinding of stone particles that may be present in the grain) – which is why we are happy to offer a 24-year guarantee on our natural stones.

- A granite millstone therefore protects your teeth and you won’t notice any unpleasant, crunching stone grit in your flour.

- We guarantee to regrind the granite millstones free of charge within 12 years if necessary. This demonstrates the optimum self-sharpening of the stones.

Our granite stones, each pair individually, are carefully and painstakingly matched and worked by hand.

Each pair of stones is unique!

The built-in granite grindstones prove extremely durable: after often decades of use, granite grindstones can be reworked by us and can then be regarded as completely new again.

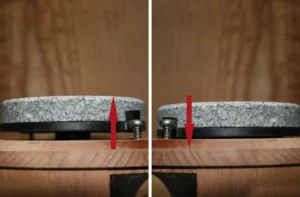

The stainless steel thread

MT 18 grain mills

MT 18 grain mills

- Together with the grinding stones, the stainless steel thread is the most important part of the mill

- Guaranteed finest flour for decades

- No grain is as hard as steel – whether kamut, maize or chickpeas

- Guarantees no change in flour fineness during grinding

Not only the stones are important for the fineness of your flour, but also the adjustment system.

The stones grind fine or coarse flour in direct interaction with the adjustment – just as you wish. This is usually the case when the grinder is purchased, but it should still work perfectly even after decades.

Regardless of whether you turn an adjusting wheel or a funnel or operate a slider, you always change the distance between the stones.

Our stainless steel threads work with millimetre precision.

Wood grinding chamber & hopper

The wood of the grain mill is exposed to the greatest stress in the grinding chamber. The grinding stone grinds the grain with great force, which grinds against the outside or bottom of the grinding chamber due to the rotation of the stone.

Abrasions from the grinding chamber can get into your flour – which is why we only use solid, untreated and, above all, hard wood.

Abrasions from the grinding chamber can get into your flour – which is why we only use solid, untreated and, above all, hard wood.

According to the latest findings, natural beech wood has an antibacterial effect – it is also well known that wood has an antistatic effect!

Cleaning the grinding chamber is not time-consuming and is only necessary from time to time. Using the grain mill continuously is the best thing you can do. Then no moths or other vermin will nest in your mill.

If you do not want to use the grinder for a longer period of time, open the grinder and use a vacuum cleaner to suck out any flour residue. It is best to leave the Salzburg grain mill open – at normal room temperature

The coarse-fine setting

The coarse/fine adjustment of the grinder is one of the most important components for a consistently fine grinding result

The coarse/fine adjustment of the grinder is one of the most important components for a consistently fine grinding result

Coarse or finest adjustment can be operated with one hand.

We do not use the plastic thread commonly used today, but only change the grinding fineness by raising and lowering the lower grinding stone.

Our ingenious, wear-independent, functional adjustment system has been adopted from vehicle clutch construction and is the logical guarantee for fine flour, even after decades!Each degree of fineness can be infinitely adjusted by hand – even during grinding.

Why wood instead of plastic?

Wood is part of human history and is a living, organic material.

Real wood is nature and fulfils the desire for authenticity in an artificial world.

Anyone who owns a natural wood kitchen will appreciate the benefits of wood. Food stays fresh for longer in the solid wood cabinet, bread stays fresher.

The latest studies have even shown that the natural substance has bacteria-inhibiting properties.

Germs cannot grow on natural wood surfaces

Technical data grain mill MT 18

Fine grinding performance: approx. 270 g/min

Coarse grinding performance: approx. 580 g/min

Weight: 24 kg

Hopper content: 1700 g

Stand surface: 25 cm

Height: 47 cm

Coarse-fine control: infinitely variable

Grinding stone: granite

grinding stone diameter: 120 mm

Grinder bearing: elastic Grinding

chamber: beech wood

Funnel and base: solid, local beech wood

Housing: molded wood

Surface treatment Housing: organic beeswax oil

Power: 900 watts

Voltage: 230 V, 50 Hz

Grinding speed: 850 rpm

Guarantee for the mill: 12 years! In addition, the stones are reground free of charge if necessary.

Guarantee for the grinding stones: 24 years! The granite stones are replaced free of charge if the grinding performance is impaired by breakage or breakage.

Additional information

| Weight | 22 kg |

|---|---|

| Dimensions | 40 × 45 × 70 cm |